Contact Us

Complete the simple form below to find out more about PU Anti-Skid for Roads Grip 3VHB-1 – we’ll be in touch as soon as possible!

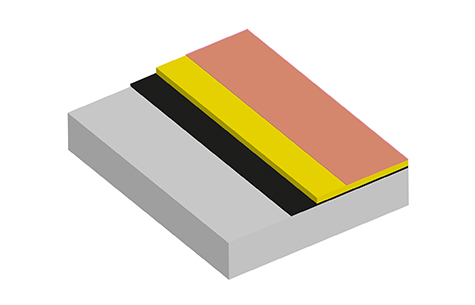

PU Anti-Skid for Roads Grip 3VHB-1

DESCRIPTION

A high performance, flexible polyurethane based anti-skid system for installation onto steel substrates. The system gives a hard wearing anti-skid surface and has been formulated with the additional flexibility required for installation onto steel.

USES

- Bridges

- Loading Ramps/Areas

- Heavy Duty Road Dressing

BENEFITS

- Anti-Skid Surface

- High Build System

- Fast Curing

- Excellent Wear Performance

- No odour

- Resistant to oil, diesel & petrol

Contact us for more information

PRODUCT SPECIFICATION

Product: Leeson Grip 3VHB-1 (PU4018/20)

Thickness: 3-5mm of PU Resin

SUBSTRATE REQUIREMENTS

The metal substrate should be prepared to S.A. 2.5 with minimum surface texture of 60 microns. Temperature +3˚C above the dew point and rising.

Metal: PU5015 primer required.

PRODUCTS INCLUDED IN THIS SYSTEM

| Primer: | Leeson Metal Primer (PU5701) | 0.1kg/m2 |

| Bonding Coat: | Leeson Grip 3-1 VHB (PU4018/20) | 3kg/m2 (1-3mm aggregate) |

| 5kg/m2 (3-5mm aggregate) | ||

| Aggregate: | Non-slip aggregate 1-3mm 8kg/m2 | |

| Non-slip aggregate 3-5mm 13kg/m2 |

Detailed installation instructions are available on request

INSTALLATION SERVICE

The installation should be carried out by an experienced contractor, details of contractors in your area can be obtained by contacting the company. For BBA approved work, a contractor approved by the BBA for this system must carry out the installation.

IMPORTANT NOTE

Leeson Polyurethane’s products are guaranteed against defective materials and manufacture and are sold subject to its standard Terms and Conditions of Sale, copies of which can be obtained on request.

Download Datasheet

Contact us for more information

TECHNICAL INFORMATION

The figures below are typical properties achieved in laboratory tests at 21˚C and 55% Relative Humidity.

TEMPERATURE RESISTANCE

Resistant to extreme temperatures (-20˚C to +120˚C) for long periods.

CHEMICAL RESISTANCE

To various acids, diesel and petrol as well as strong bases.

TENSILE STRENGTH (3VHB-1)

6 N/mm2 to BS2782 Part 3

ELONGATION @ BREAK (3VHB-1)

15% to BS2782 Part 3

TENSILE ADHESION (MILD STEEL)

12.5N/mm2

SPEED OF CURE

Traffic Ready: 2 hours @ 20˚C

AFTERCARE – CLEANING AND MAINTENANCE

Clean as required, remove any loose aggregate after initial traffic.

ENVIRONMENTAL IMPACT

The finished system is assessed as non-hazardous to health and the environment. The long service life and seamless surface reduce the need for repairs, maintenance and cleaning. Environmental and health considerations are controlled during manufacture of the products by Leeson Polyurethanes staff.

FURTHER INFORMATION

To ensure you are specifying a fit for purpose surface for your project please consult our Area Sales Manager for your area or contact us on lpusales@icpgroup.com.

Available in Black and Grey

Available in Black and Grey