Call: +44(0)1926 833367

MenuTechnical

Leeson Polyurethanes offers our customers strong technical support in all areas of our business. We understand that many customers may be using our products for the first time, while others may have used them before, and some customers are looking for a bespoke polyurethane product; all of whom require varying levels of technical support. The knowledge and dedication of the technical team are second to none and through their innovation and skills they bring ideas to life.

Working as a Team

Shared knowledge and communication to put the customer first

The Technical department and Sales team work very closely together to design the optimum products for our customers. When new customers make initial contact and are looking for something that we don’t already offer, the two departments discuss how we can formulate the best product to suit their purpose.

Technical Department

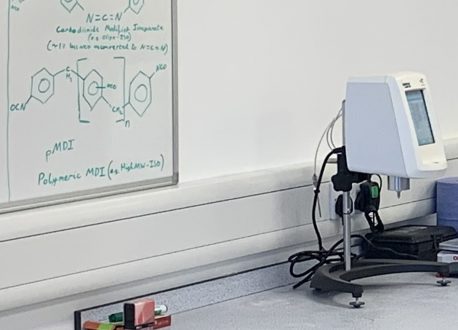

Leeson Polyurethanes has a dedicated laboratory utilised for quality control testing and product development.

Quality Assurance

Our products are manufactured to stringent procedures, and every batch made is individually quality checked by our laboratory prior to approval for despatch. We operate under an ISO 9001:2015 aligned Quality System, which is externally audited by the BBA.

New Product Development

Our polyurethane specialised laboratory develops all of our products in house. This gives us the ability to offer our customers a high degree of flexibility in formulations, tailoring them to their precise needs.

Customised Testing Procedures

We work closely with our customers to produce testing procedures that match their final application requirements. These include:

Taber Abrasion: The resistance to abrasion of a product can be tested.

Instron: Products are tested to destruction, recording the Tensile Strength and Elongation.

Panel Press: Allowing our lab to produce panels with Leeson adhesive products with customer substrates to confirm suitability.

Spectrophotometer: Allowing colour matching to be performed on products.

Slip Resistance Tester: Allowing testing to be performed in-lab and onsite to confirm the level of slip resistance for surfaces.